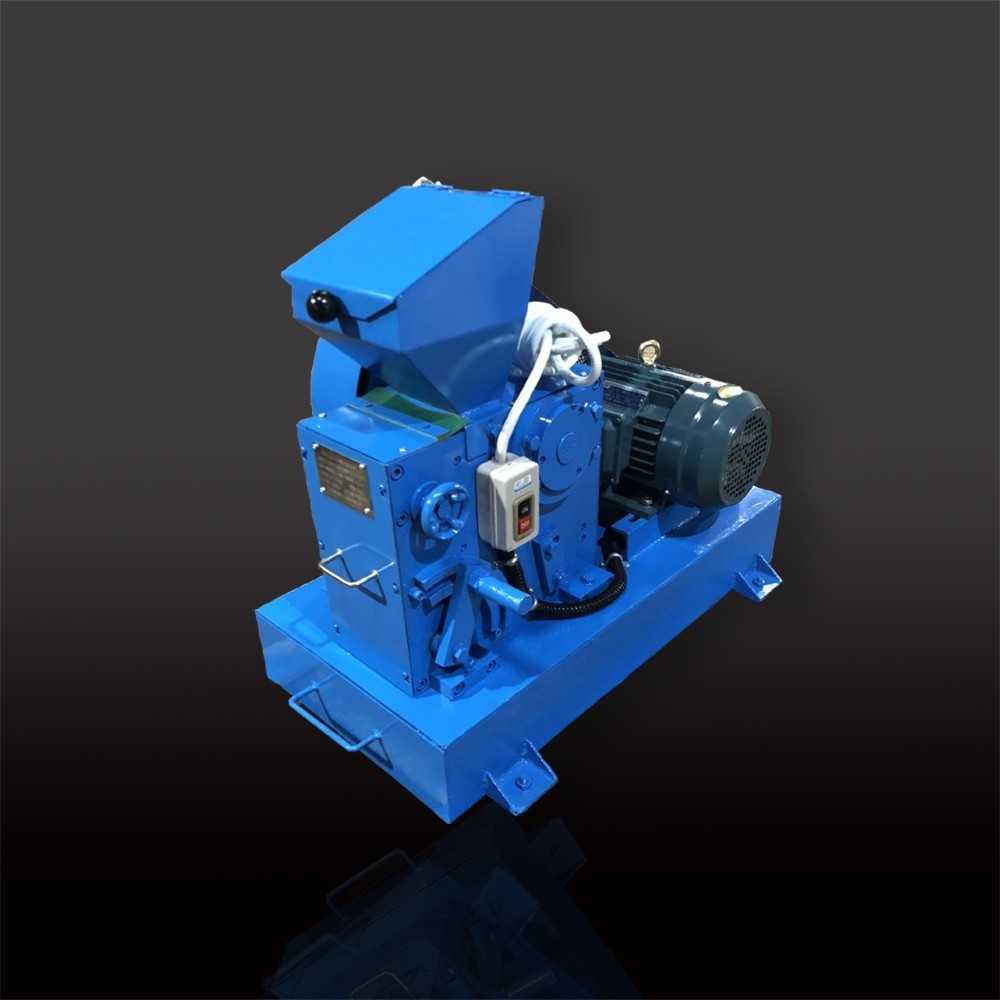

Lab Jaw Crusher

GTEK Laboratory Jaw Crusher have a wide range of applications across many industries such as mining, metallurgical industry, coal, geology and chemistry.

Description

GTEK Laboratory Jaw Crusher has been specially designed for rapid and effective crushing and pre-crushing of medium-hard rocks and ores. It is compact and of rugged construction for general laboratory or small pilot plant operations.

GTEK Laboratory Jaw Crusher consists of a stationary plate with an opposing moving jaw plate. Reduction takes place as material is trapped in the gap between the two plates and fractured with compressive force. Particle size can be controlled by adjustment of the width, or gap between the jaws. To avoid metallic contamination, the grinding chamber of the jaw crusher is available of ceramic materials.

Working Principle

Lab Jaw Crusher is consist of iron housing, eccentric shaft, movable jaw seat, fixed jaw plate and so on. The eccentric shaft was rotated by the motor through V-belt wheel. The movable jaw seat with movable jaw plate is moving along with the eccentric under the expected trajectory, and causing collision extrusion with relatively fixed jaw plate in the fixed jaw plate seat, and thus crushing cavity material according to the requirements needed to be broken.

Discharge open size can be adjusted by adjusting seat in the eccentric shaft and change the position of the eccentric shaft to achieve the desired particle size.

Features

1. Powerful size reduction;

2. Simple structure, easy maintenance;

3. Stable performance and low noise;

4. Even final particles and high crushing ratio.

Model | Feed Opening Size (mm) | Feed Size (mm) | Regulation Range of Discharge Opening (mm) | Capacity (kg/hr) | Main Shaft Speed (rpm) | Motor Power (kW) | Weight (kg) |

PEF60×100 | 60×100 | ≤50 | 1-6 | 45-550 | 600 | 2.2 | 186 |

PEF100×100 | 100×100 | ≤80 | 3-25 | 400-1800 | 500 | 3 | 240 |

PEF100×125 | 100×125 | ≤80 | 5-25 | 400-1800 | 500 | 3 | 250 |

PEF100×150 | 100×150 | ≤80 | 5-38 | 400-1800 | 500 | 3 | 360 |

PEF125×150 | 125×150 | ≤100 | 6-38 | 500-1800 | 500 | 3 | 1000 |

PEF150×250 | 150×250 | ≤125 | 10-40 | 1000-3000 | 350 | 7.5 | 1200 |