Lab Double-Roll Crusher

GTEK Laboratory Double Roll Crusher is designed for intermediate crushing of medium hard materials such as coal, coke, limestone, phosphosiderite, sulfur ore and coal gangue. Double roll crusher is widely used in laboratory of mining, metallurgical, coal, construction industry and etc.

Ask For Quote Donwload

Description

GTEK Laboratory Double Roll Crusher is designed for intermediate crushing of medium hard materials such as coal, coke, limestone, phosphosiderite, sulfur ore and coal gangue. Double roll crusher is widely used in laboratory of mining, metallurgical, coal, construction industry and etc.

GTEK Lab Double-Roll Crusher is suitable for crushing of different kinds of ore with compression strength no more than 2000Kg/cm2.It has the characteristic of simple structure, even final particles, lower energy consumption, longer service time and easier maintenance.

Working Principle

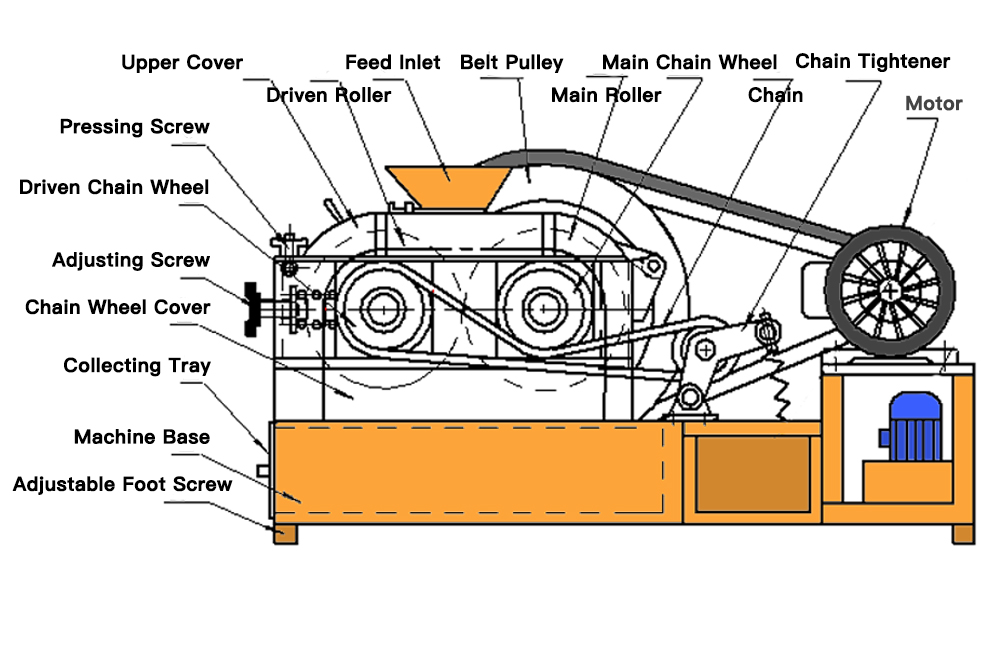

Lab Double-Roll Crusher is consist of the machine base, machine body, rollers, chain wheel, etc.The main drive roller is driven to run by the motor via roller belt, the main roller drive the driven roller to run synchronously by means of chain.Materials falling into the crushing chamber are crushed.This Lab Double-Roll Crusher has body and coupled with adjusting screw at the back of the body.There are protection cover at both side of the base, so as to ensure safety.There are screws and bearing seat mounted on the machine body, the springs are mounted at the front of the body which is ease of adjustment. On the left side,the motor drives the main roller, while on the right side, the main chain wheel drives the driven chain wheel to run synchronously.The benefits of chain driving is lower noise and stable operation. When adjusting the driven roller, pay attention to the two screws on left and right sides to ensure same pressure, so as to avoid equipment failure, ensuring safety use.

Features

1. Efficient for crushing of materials with moisture content less than 15%;

2. Even final particles, no flaky and sticky materials;

3. Excellent design and easy operation.

Model | Roll Size (mm) | Max. Feeding Size (mm) | Discharg-e Size (mm) | Capacity (kg/hr) | Roll Rotation Rate (r/min) | Dimensions (mm) | Motor Power (kW) | Wght (kg) |

XPC200×75 | Φ200×75 | ≤13 | ≤1 | 100 | 320 | 1000×500×650 | 1.5 | 260 |

XPC200×100 | Φ200×100 | 200 | 1000×500×650 | 2.2 | 300 | |||

XPC200×125 | Φ200×125 | 250 | 1000×500×650 | 3 | 375 | |||

XPC200×150 | Φ200×150 | 500 | 1000×500×650 | 4 | 400 |